The Robovikes attended their home town competition in Davis California March 22- 24, 2018. Along side us in competition was Buckingham, Armijo and Napa who we cheered on greatly.

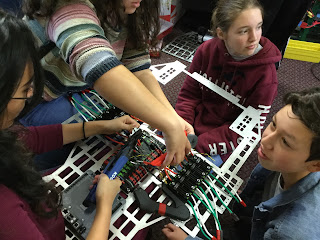

A few of our students were very generous with their time and helped team 3013 Vallejo Robotics. They were very appreciative and it was definitely a good representation of Team 701s outreach.

Because of our work in STEM and spreading it to our community, The Robovikes won Engineering Inspiration Award sponsored by NASA. This award is a second to chairmens, making it the 2nd most prestigious award in FIRST. The award includes NASA sponsoring our robot to be entered in the competition.

A few of our students were very generous with their time and helped team 3013 Vallejo Robotics. They were very appreciative and it was definitely a good representation of Team 701s outreach.

Because of our work in STEM and spreading it to our community, The Robovikes won Engineering Inspiration Award sponsored by NASA. This award is a second to chairmens, making it the 2nd most prestigious award in FIRST. The award includes NASA sponsoring our robot to be entered in the competition.